Mastery of Production Operations Management: Foundation of Effective Systems of Production

Effective Production Operations Management is absolutely vital for companies trying to maximize their Production and Operation Management procedures in the hectic and very competitive corporate climate of today. This discipline guarantees that manufacturing processes function cost-effective, efficient, and faultless, therefore increasing production and customer satisfaction. We shall examine the nuances of Production Operations Management, investigate the function of a Production System in Production Management, and underline important techniques to improve operational efficiency in this paper.

Production in Operations Management : Definition

Planning, organizing, directing, and controlling the activities engaged in the manufacturing of goods and services is what Production Operations Management (POM) is all about. It covers all aspect, from supply chain management and quality control to workflow design and resource distribution. POM’s main objectives are to guarantee that manufacturing processes are cost-effective, efficient, and fit for organizational goals.

Fundamentally, Production Operation Management is about turning labor, tools, and raw materials into completed goods or services satisfying consumer needs. In production management, a well-organized production system serves as the foundation for all operational activities and so promotes this transformation process.

In production management, the function of a production system

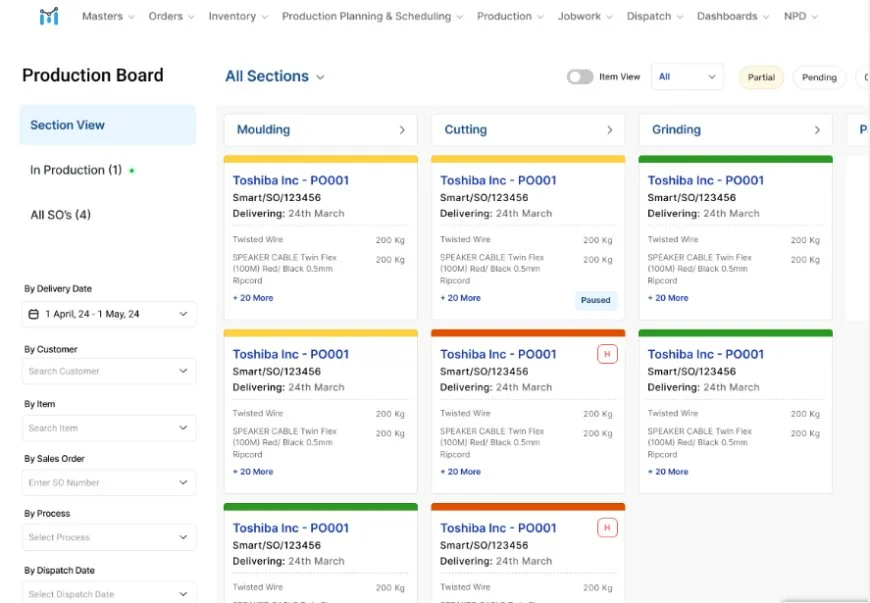

In production management, a production system is the arrangement of people, tools, machinery, and technologies cooperating to generate goods or services. Any manufacturing or service-oriented company’s foundation is its ability to guarantee best use of resources to reach intended results.

Production systems mostly come in two forms:

Often used in sectors including oil refining, chemical manufacture, and food processing, this system is defined by constant production of goods. It is mass production oriented and somewhat mechanized.

Intermittent Production System: This system is used for producing goods in smaller batches or on a made-to-order basis. It is more flexible and adaptable, making it suitable for industries like custom manufacturing, fashion, and furniture.

Regardless of the type, a well-designed Production System in Production Management ensures that production processes are streamlined, waste is minimized, and quality is maintained.

Key Components of Production Operations Management

To achieve operational excellence, organizations must focus on several critical components of Production Operations Management:

Production Planning and Control: This involves forecasting demand, scheduling production activities, and monitoring progress to ensure that production targets are met. Effective planning minimizes downtime and ensures that resources are used efficiently.

Inventory Management: Proper management of raw materials, work-in-progress, and finished goods is essential to avoid overstocking or stockouts. Techniques like Just-In-Time (JIT) and Economic Order Quantity (EOQ) can help optimize inventory levels.

Quality Management: Ensuring that products meet or exceed customer expectations is a cornerstone of Production and Operation Management. Tools like Total Quality Management (TQM) and Six Sigma can help maintain high-quality standards.

Supply Chain Management: A robust supply chain ensures that materials and components are delivered on time and at the right cost. Collaboration with suppliers and distributors is key to maintaining a seamless flow of goods.

Maintenance Management: Regular maintenance of machinery and equipment is essential to prevent breakdowns and ensure uninterrupted production. Predictive and preventive maintenance strategies can help reduce downtime and extend the lifespan of assets.

Strategies to Enhance Production Operations Management

To stay ahead in today’s competitive landscape, organizations must adopt innovative strategies to enhance their Production Operations Management. Here are some proven approaches:

Leverage Technology: The integration of new technologies like Artificial Intelligence (AI), Internet of Things (IoT), and automation can change manufacturing processes. For example, IoT-enabled equipment can provide real-time data on machine performance, enabling proactive decision-making.

Implement Lean Manufacturing: Lean concepts focus on eliminating waste and enhancing efficiency. Techniques like value stream mapping, 5S, and Kaizen can help streamline operations and save expenses.

Adopt Agile Methodologies: Agile methodologies stress flexibility and response to changing market demands. By breaking down production processes into smaller, manageable activities, businesses can react swiftly to new difficulties.

Focus on Employee Training: Skilled and motivated personnel are the backbone of any successful manufacturing system. Regular training programs can strengthen their technical skills and problem-solving ability.

Track Key Performance Indicators (KPIs): Monitoring indicators of production output, cycle time, and defect rates will help one get important understanding of operational performance. This data-driven method makes ongoing improvement possible.

Difficulties in Production Operations Management

Production operations management presents difficulties even if it is rather important. Some typical problems consist:

Production efficiency can be hampered by limited supply of capital, manpower, or raw goods.

Natural disasters, geopolitical concerns, or pandemics can all throw off the supply chain and cause delays and higher prices.

Technological obsolescence: Quick technological developments can make current production systems obsolete and call for expensive updates.

Maintaining constant quality over significant production can be difficult, particularly in sectors with strict regulatory needs.

Organizations who want to overcome these obstacles have to approach production and operation management strategically and proactively.

The Evolution of Production Operations Management

Production operations management will keep changing in response to new trends and technology as we gaze ahead. Among important events to observe are:

Characterized by smart factories and cyber-physical systems, Industry 4.0 — the fourth industrial revolution — will alter manufacturing processes.

Growing focus on environmental responsibility will help green manufacturing techniques to be adopted.

Growing consumer demand for individualized goods will call for more adaptable and flexible manufacturing techniques.

Globalization: Approaching Production and Operation Management more holistically and cooperatively will be necessary when entering foreign markets.

Conclusion

Ultimately, the success of every company engaged in manufacturing or service delivery depends on the vital ability of production operations management. Through better efficiency, cost control, and delivery of premium products to their consumers, companies can maximize the production system in production management. Maintaining ahead of the curve in the ever changing corporate environment will call for strategic planning, constant improvement, and innovative commitment. Whether your company owner wants to improve your manufacturing processes or you are a seasoned operations manager, long-term success depends on your mastery of the ideas of Production System in Production Management.

Organizations may create a strong and resilient manufacturing system that drives expansion and profitability in a world growing more competitive by concentrating on the essential components, implementing creative ideas, and confronting issues head-on.

What's Your Reaction?